What is INDUSTRY 4.0 ERP? INDUSTRY 4.0 and ERP

This article is relevant to anyone interested in Industry 4.0 and ERP technology, particularly those in the manufacturing, wholesale, and distribution businesses. It provides an overview of the different Industry 4.0 technologies, including IoT, simulation, horizontal and vertical integration, cloud computing, additive manufacturing, augmented reality, big data and analytics, and cyber-physical systems, and how they can be integrated with ERP systems. The article also discusses the benefits of adopting Industry 4.0 technologies and integrated ERP systems, and how cloud-based solutions can simplify implementation and maintenance.

Industry 4.0 is a new stage in the industry that concentrates on interconnectivity, automation, machine learning, and real-time data. It is investing in technology and tools to enhance manufacturing and distribution efficiency and effectiveness. It is about revolutionizing the way business operates and grows by applying real-time data and information interconnected by IoT sensors.

The benefits of integrating Industry 4.0 technologies and ERP systems will be very high, especially in support of intelligent machines and processes, data analytics, and modeling, which can help companies in the real-time decision-making process. Modern ERP systems support Cyber-Physical Systems, which lead to feature end-to-end vertical integration, from inbound logistics, planning, and marketing to outbound logistics, and services.

Industry 4.0 ERP systems’ role has changed from a central database system that collects data to supporting mobile role-based user interactions. Legacy ERP systems need to be redesigned or replaced for Industry 4.0 for the FoF (Factory of Future). It will require real-time two-way communication between machines, processes, and products.

Table of Contents

- Simulation

- Horizontal and Vertical Integration

- Cloud Computing

- Additive Manufacturing

- Augmented Reality

- Internet of Things

- Big Data and Analytics

- Cyber-physical systems

- Benefits of Adopting an Industry 4.0 technologies

- Industry 4.0 and Cloud-based ERP technology

- Distributors and Wholesalers Cloud ERP: Industry 4.0

Industry 4.0 contains nine technologies, and each of them is related to the ERP systems; somehow, some are analyzed below.

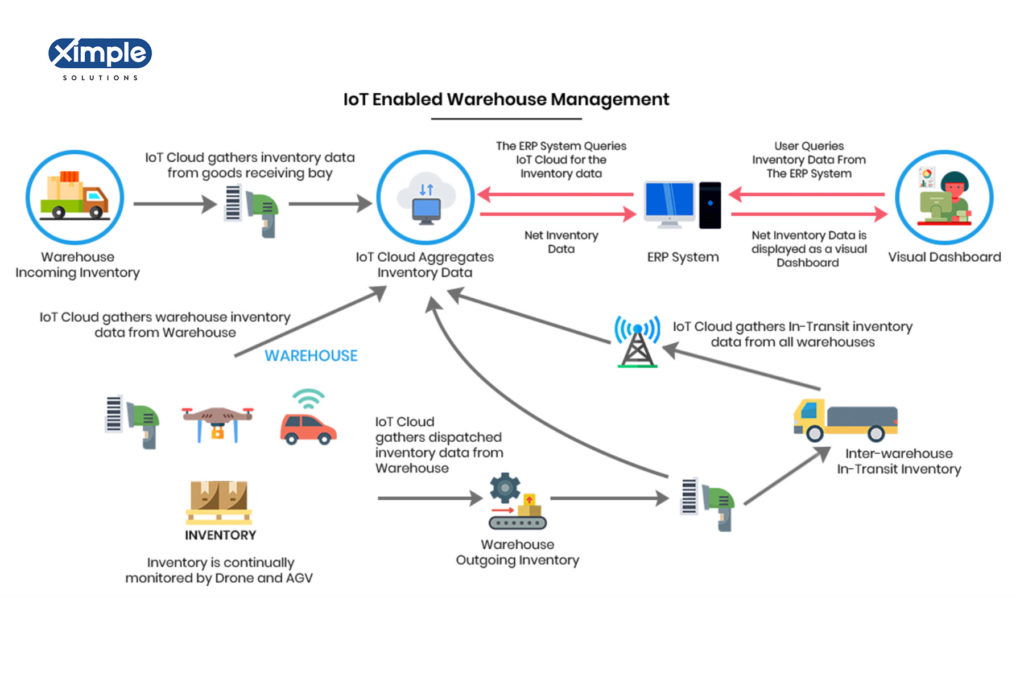

The Internet of Things (IoT) is the first industry 4.0 technology, which should be supported by ERP systems. IoT is an integration point of Industry 4.0 and ERP. Nowadays, in most cases, data from manufacturing, Warehouses, production planning, distribution, quality control, processes, and other sources are entered manually into ERP systems. The use of IoT would help automatically enter data into ERP systems, which are collected from different production sources. This would have the effect of eliminating data entry errors. Entering data through the use of IoT equipment would also help in changing the approach to ERP systems.

Simulation

A simulation is a tool for predicting and evaluating the performance of systems. It helps companies optimize the decision-making process, which provides the “smart brain†required to improve industrial systems’ efficiency. Companies can simulate real-world situations in a virtual model to help companies optimize products and places in the virtual world before the physical setup.

Simulation can relate to ERP through Big Data Analytics for predicting and evaluating the performance of systems that optimize the resources.

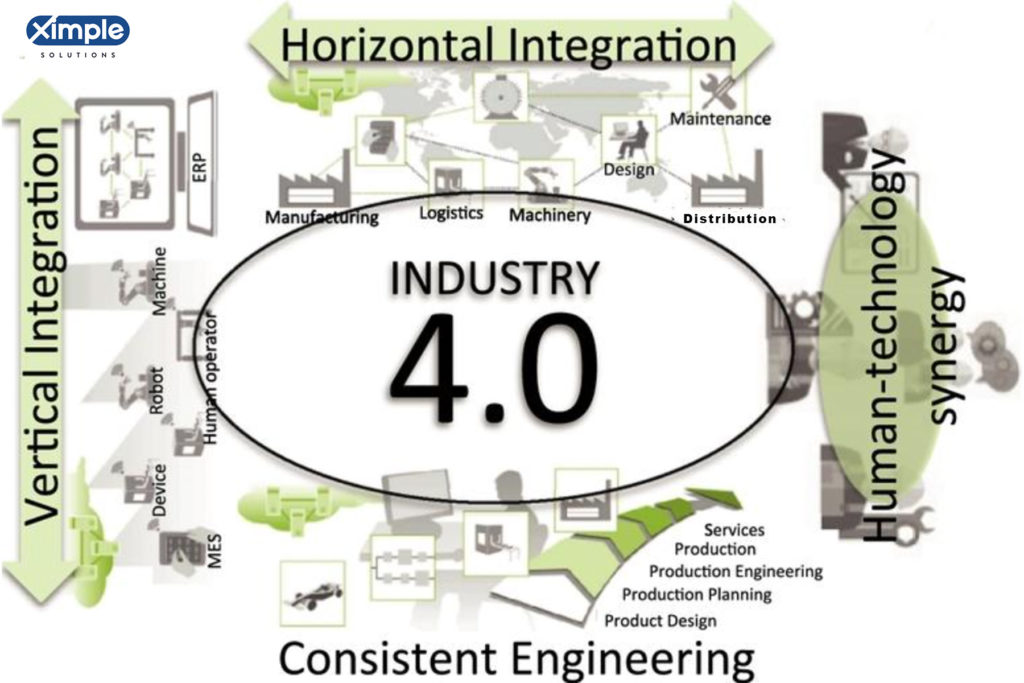

Horizontal and Vertical Integration of INDUSTRY 4.0 ERP

Horizontal integration implies the connection between all the value chain components, starting from internal company logistics, production, distribution, sales, and services, to external partners, suppliers, customers, and energy suppliers to create a value chain as autonomously acting participants.

Vertical integration connects different company levels with IT systems in production, distribution manufacturing, and low-level PLC (Programmable Logic Controller) machine controllers & sensors within the company to increase flexibility and performance in planning management.

By using the Horizontal and Vertical integration approach supported by ERP systems, autonomous production methods can be powered by Robots that can complete tasks intelligently, with a focus on safety, flexibility, versatility, and collaboration. This integration would be a benefit in generating value for customers, creating a new competitive environment, and increasing company productivity, and global economic growth.

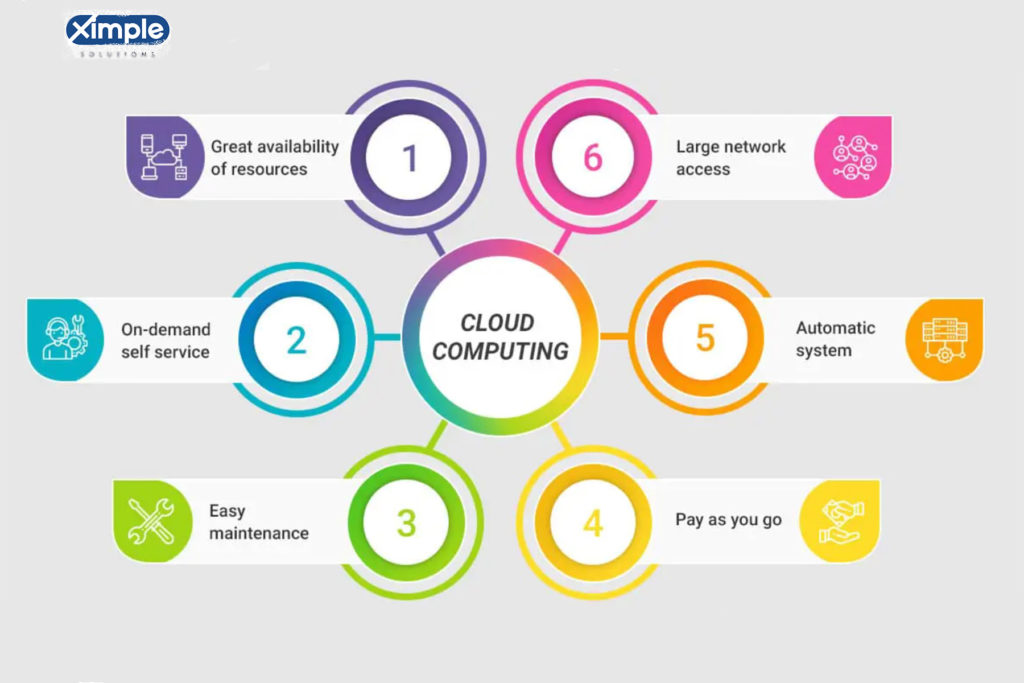

Cloud Computing

Cloud computing is defined as an Internet-based service or IT infrastructure, starting from applications delivered as a service or hardware and software in the data centers. The Cloud computing is divided into three categories.

1. Software as a service (SaaS): a software model where a provider licenses an application delivered over the internet.

2. Platform as a service (PaaS): a software development framework and components delivered on the network. The PaaS model is a platform that includes an operating system, programming language execution environment, database, and web server. A PaaS client can develop and run its applications at the software layer.

3. Infrastructure as a service (IaaS): an integrated environment of computing resources, storage, and network fabric delivered over the network. Offered as an on-demand, pay-for-usage model.

Additive Manufacturing

Additive Manufacturing is a technology that allows companies to produce a prototype, individual components, and 3-D printing. “With Industry 4.0, additive-manufacturing methods will be widely used to produce small batches of customized products that offer construction advantages, such as complex, lightweight designs. High-performance, decentralized additive manufacturing systems will reduce transport distances and stock on hand“.

Augmented Reality (AR)

It can combine the physical, and real-world environment information by adding virtual data generated by computers. The main advantage of AR is the ability to integrate the virtual environment and real-world interaction. Augmented Reality-based systems nowadays are used in different aspects in a real-time situation, starting from warehouses, and maintenance instructions, which helps the users of this technology improve decision-making and work procedures.

It can use data stored in the INDUSTRY 4.0 ERP system and choose accurate information for boosting it for scene processing and visualization of the augmented scene.

Internet of Things

There are many reasons to apply the Internet of Things in the Industrial fields. The companies can reduce the cost of operation and prevent the production line’s failure or stoppage in the future. The companies gain extra profit via service-oriented production system, and the managers’ needs will be satisfied for easier decision makingâ€. The application of Internet of Things devices can contribute to the data reading and transferring to the central databases; simultaneously; this equipment allows automatization of the data entry, which reduces data entry errors and data processing time.

Big Data and Analytics

Big data can help companies analyze the past, and present, and predict the future using an analytical application to generate value from the available data. There is a link between ERP and Big Data Analytics and the other technologies of Industry 4.0. With Big Data Analytics, ERP systems can enable the collection and evaluation of data from different sources in real-time. They can help in decision-making, quality control, optimizing costs, and other aspects.

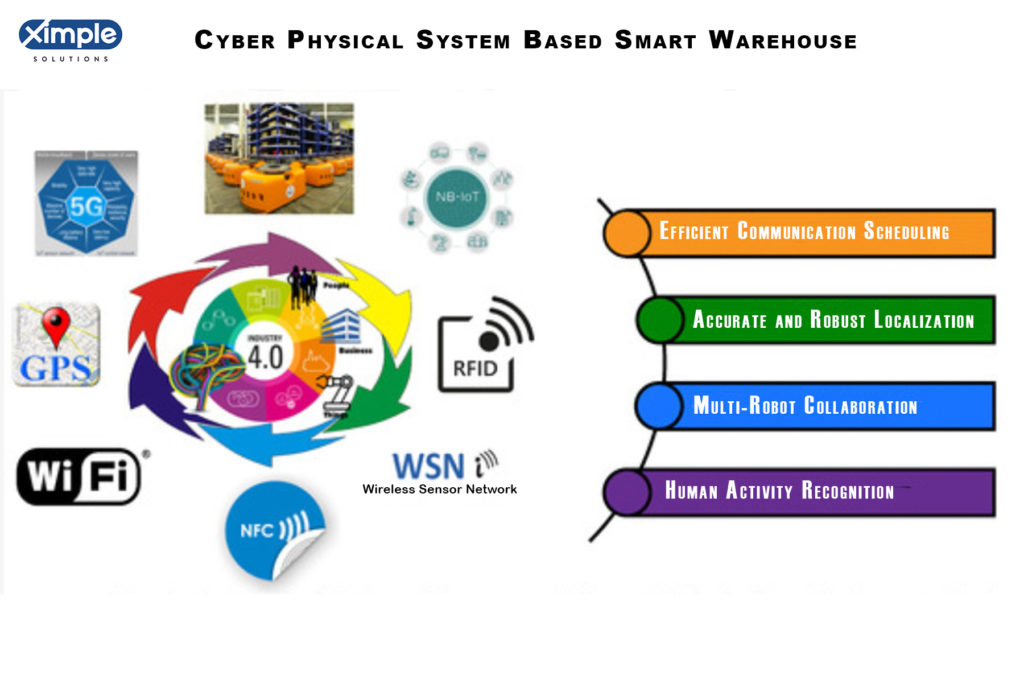

Cyber-physical systems (CPS)

Cyber-physical systems, also sometimes known as cyber distribution, refer to an Industry 4.0-enabled distribution environment that provides real-time information collection, evaluation, and transparency in every part of a distribution operation.

Benefits of Adopting Industry 4.0 technologies and integration with ERP

It offers tools to be more competitive, especially against disruptors like Amazon. As companies like Amazon still optimize logistics and provide chain management, one needs to invest in Industry 4.0 and ERP technology to improve and optimize manufacturing and distribution business operations. It will offer an equivalent or better level of service than corporations like Amazon.

It offers a competitive edge to hiring a talented young workforce. Companies that invest in modern, innovative Industry 4.0 technologies and Modern Cloud-based ERP are better positioned to draw in and retain new workers.

Companies that invest in Industry 4.0 and Modern Distribution ERP solutions can increase efficiency, boost collaboration between departments, enable predictive and prescriptive analytics, and permit people, including operators, managers, and executives, to more fully leverage real-time data and intelligence to form better decisions while managing their day-to-day responsibilities.

Industry 4.0 Integrated ERP allows dealing with potential issues before they become big problems. Predictive analytics, real-time data, internet-connected machinery, and automation can all assist in being more proactive when it involves addressing and solving potential maintenance and provide chain management issues. Top-rated Distribution and Wholesale ERP with Industry 4.0 trims costs, boost profits, and fuel growth. Industry 4.0 technologies optimize all aspects of the manufacturing, wholesale, and distribution business. It gives real-time access to real-time data and insights for smarter, faster decisions about distribution and manufacturing business, which may ultimately boost the entire operation’s efficiency and profitability.

Can we have the resources and staff to implement and manage Industry 4.0 and Cloud-based ERP technology?

Cloud-based technologies and ERP do not need a large IT team to manage and maintain systems. Even regular updates and maintenance are performed by the service provider. Legacy ERP systems have massive implementation and upgrade challenges. This challenge could be easily overcome by leveraging cloud-based Distribution and Wholesale ERP or software as a service (SaaS) or Platform as Service (PaaS). Like cloud storage, the cloud ERP provider assumes the prices otherwise borne by IT to create and maintain infrastructure. A cloud-based ERP system provides all of the advantages of ERP without requiring dedicated IT infrastructure or staff and frees those resources to be utilized in other IT tasks.

FAQ about INDUSTRY 4.0

What are Industry 4.0 technologies?

The meaning of Industry 4.0 is the fourth industrial revolution. Thus, there were the first, second, and third industrial revolutions before the fourth one emerged. Industry 4.0 entails cyber systems and technologies. So it includes the Internet of Things (IoT), cyber-physical systems (CPS), cloud computing, AI (artificial intelligence), cognitive computing, and smart factories and manufacturing. Industry 4.0 technologies allow automation in the manufacturing sector by creating factory machines with Wi-Fi connectivity and sensors for monitoring and visualization.

Is Industry 4.0 Software?

Industry 4.0 is a software solution that automates manufacturing to enhance efficiency, safety, customer experiences, and problem-solving. It refers to digital technologies. This technology allows you to monitor your production process at every stage via sensors that provide real-time information. Industry 4.0 does not include robotics, but it can connect robots to work together or put them in different areas of the production process.

What are Industry 4.0 applications?

Industry 4.0 has many applications in the modern world. Meanwhile, it allows companies to automate administrative tasks to ensure that humans no longer handle these repetitive jobs. Machines and software can reduce human errors like duplication, incorrect data, omissions, and outdated data.

As we said earlier, Industry 4.0 technologies facilitate manufacturing work by installing wireless sensors on factory machines to monitor and gather data. Thus, you can track, identify, and correct issues before they worsen. The Industrial Internet of Things is possible due to Industry 4.0 technologies.

Industry 4.0 also has applications in intelligent processes where machines can analyze data and predict when to maintain it. They can even reserve a technician to help with the repairs. An advanced analytic software tool can help us mine data to pinpoint the most efficient product and maintenance scenarios.

With an Electronic Data Interchange system, companies can exchange documents electronically rather than manually. That’s because Industry 4.0 allows the integration of computer networks and connecting products to the internet.

Is your ERP ready for Industry 4.0?

We are in a digitalization era. So you need to ensure that your ERP system is Industry 4.0 ready. In other words, you need to consider leaving your legacy ERP in favor of the cloud ERP system. The cloud ERP connects your company to the rest of the world. It supports remote data processing in real-time.

It can help you use the internet to collaborate with your suppliers and business associates via EDI for B2B connections. Also, you can have a transactional website for B2C use.

Conclusion

A staggering 85% or more of ERP users would switch to disconnected spreadsheets if faced with poor software usability, undermining the primary purpose of enterprise applications. Ximple’s product development team prioritizes user experience, placing it at the forefront of their design, and adopts a mobile-first approach. The latest interfaces incorporate Natural Language Processing, enhancing user interaction. Ximple Cloud ERP for distribution and wholesale businesses leads the way in IoT, extensive data analytics, cognitive and process automation, as well as autonomous processes and decision-making.

Ximple Solutions’ vision for Distributors and Wholesalers Cloud ERP: Industry 4.0

To facilitate success in the Ximple product roadmap and align with Industry 4.0, we have invested heavily in R&D and built a large team of engineers to revamp and re-architect the Ximple ERP system. We plan to make an ERP solution API-driven to allow easy integration to various techniques and IoT devices, designed to make the user interface customer and user-centric and infuse artificial intelligence for autonomous business decisions on the business process level.